How Membrane Switch Technology is Revolutionizing User Interfaces

How Membrane Switch Technology is Revolutionizing User Interfaces

Blog Article

Understanding Membrane Switches: The Secret to Durable and Reliable Controls

What Are Membrane Layer Switches?

Membrane switches are an advanced option in the world of interface innovation, incorporating capability and design effortlessly. These gadgets offer as a user interface in between users and electronic systems, integrating several elements right into a compact format. Usually built from versatile, slim layers of materials, membrane switches are designed to reply to touch, enabling users to interact with machinery and electronic devices efficiently.

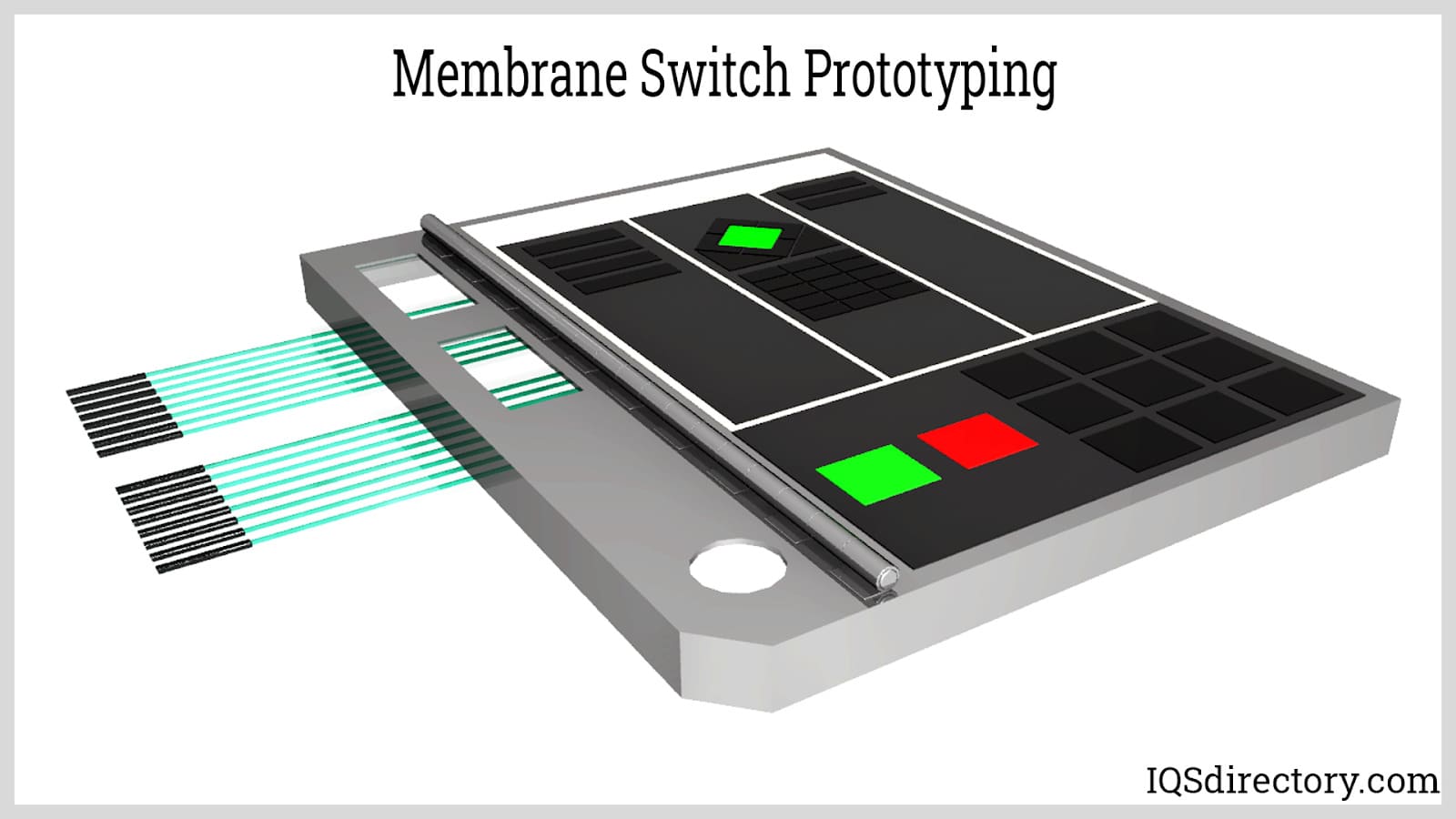

The primary elements of a membrane button consist of a printed circuit layer, visuals overlay, and a spacer layer that prevents unintentional activation. The graphic overlay can be customized to reflect brand name identification or customer choices, improving aesthetic appeals while making sure functionality. Membrane buttons are generally used in numerous applications, including medical gadgets, customer electronic devices, and commercial tools, owing to their durability and resistance to ecological aspects such as wetness and dust.

One of the crucial benefits of membrane layer buttons is their ability to withstand deterioration, making them excellent for high-traffic atmospheres. Furthermore, they are light-weight and need minimal room, enabling ingenious layouts in product development. On the whole, membrane switches over stand for a reliable and useful selection for contemporary digital user interfaces, marrying modern technology with user-centric design concepts.

How Membrane Layer Switches Over Job

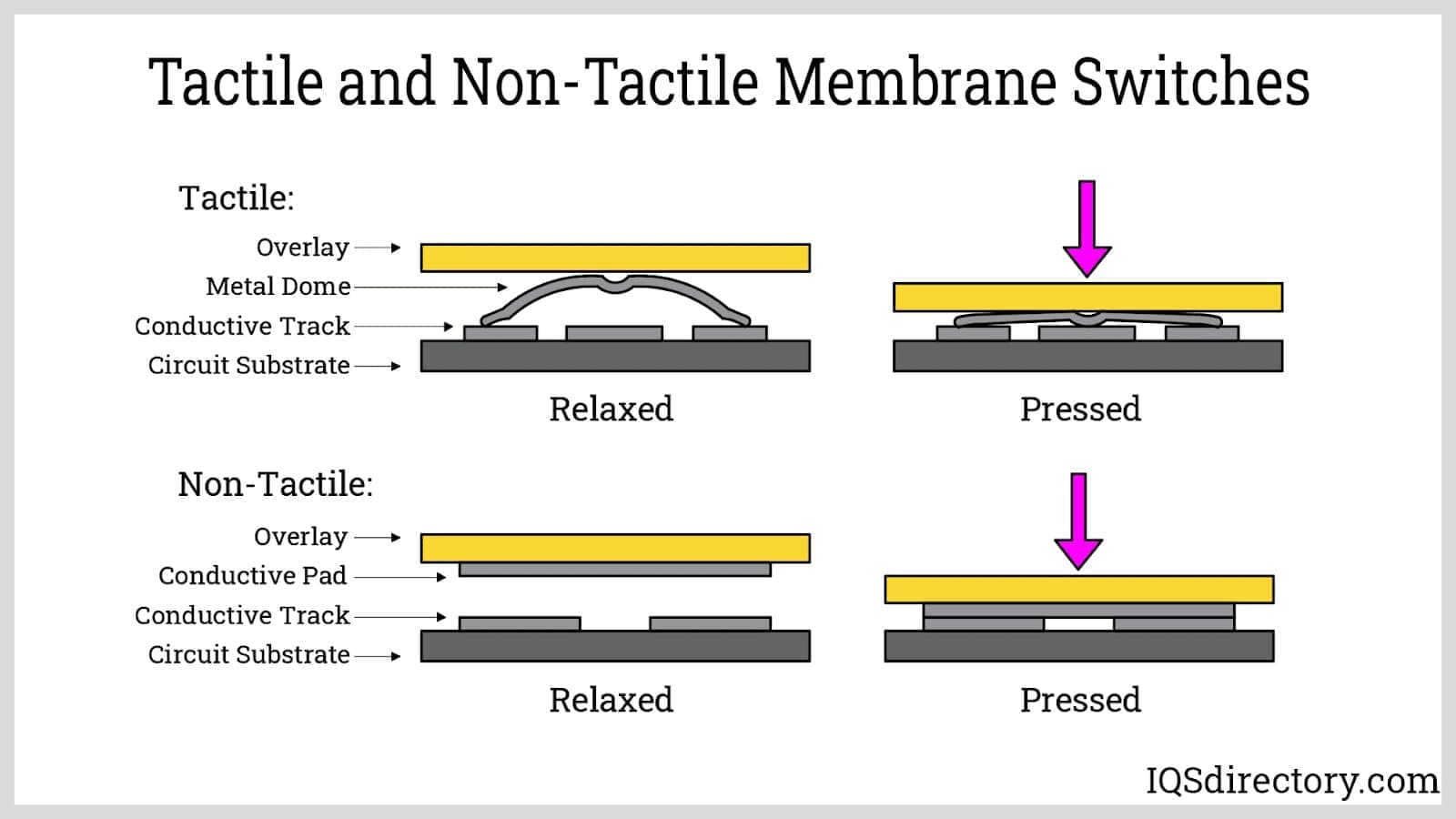

The operation of membrane layer switches depend upon a straightforward yet efficient system that translates customer input right into electronic signals. These buttons include multiple layers, typically consisting of a visuals overlay, a spacer layer, and a circuit layer. When a user presses the button, the leading layer warps, enabling a conductive component in the circuit layer to make contact with a matching conductive pad on the underside of the graphic overlay. This call closes the circuit and sends out a digital signal to the device, suggesting that the button has been triggered.

The layout of membrane buttons can differ, but they usually incorporate domes or responsive elements to offer comments to the customer, boosting the total experience - membrane switch. The products used in membrane switches, such as polyester or polycarbonate, add to their durability and resistance to environmental elements, including dampness and dirt. Furthermore, the printed circuits are generally encapsulated, which safeguards them from damage over time.

Benefits of Membrane Layer Buttons

In addition, membrane layer buttons are recognized for their resilience. Built from durable products, they are immune to dirt, moisture, and physical wear, which considerably extends their life expectancy compared to standard mechanical switches. This sturdiness makes them especially appropriate for high-traffic atmospheres and applications needing durability.

One more substantial benefit is the convenience of cleansing and upkeep. The smooth surface of membrane switches lessens dirt buildup and is usually resistant to spills, making them excellent for setups that call for constant sanitization.

In addition, membrane layer switches provide a streamlined account, bring about a thinner layout that can be incorporated into various gadgets without including bulk. This feature not just improves the aesthetic appeal yet likewise contributes to a more ergonomic product design.

Applications of Membrane Layer Buttons

Flexible and user-friendly, membrane switches locate applications throughout a wide array of markets, including clinical tools, consumer electronics, and a knockout post commercial devices. In the clinical field, these buttons are important to gadgets such as analysis devices, patient surveillance systems, and mixture pumps, where dependability and ease of cleansing are important. Their ability to maintain and stand up to severe settings functionality makes them excellent for such applications.

In customer electronics, membrane buttons are used in products like microwaves, cleaning machines, and push-button controls - membrane switch. Their sleek style enables intuitive user interfaces, enhancing the total individual experience while supplying longevity and resistance to tear and put on

Commercial equipment also profits from membrane switches, especially in control panels for equipment and automation systems. These buttons supply protection against dirt and dampness, guaranteeing constant efficiency in tough settings. Their adjustable functions enable makers to customize them to certain operational demands, enhancing effectiveness and capability.

Selecting the Right Membrane Layer Switch

When choosing a membrane switch, it is vital to take into consideration various variables that affect efficiency and suitability for particular applications. The main considerations include ecological problems, responsive feedback, sturdiness, and design specifications.

First, assess the operating setting; buttons subjected to wetness, chemicals, or extreme temperature levels call for certain materials to try these out ensure long life and capability. Next off, assess the demand for responsive comments. Depending upon user communication, some applications might profit from a tactile this website response to validate activation, while others may favor a non-tactile style for aesthetic reasons.

Longevity is an additional vital factor; membrane layer buttons should be designed to withstand regular use, influences, and abrasion. Guarantee the picked switch can sustain the anticipated lifecycle, specifically in high-usage scenarios.

Verdict

In conclusion, membrane switches over offer as necessary components in the style of trusted and resilient control systems across numerous sectors. The flexibility of membrane layer switches over allows for tailored services that fulfill certain functional needs, reinforcing their relevance in modern-day innovation.

Membrane layer switches represent a critical element of contemporary user interface layout, mixing capability with resilience in various applications.Membrane buttons are an innovative remedy in the realm of user interface technology, combining performance and style perfectly. Typically built from versatile, thin layers of materials, membrane switches are designed to respond to touch, enabling customers to connect with equipment and digital tools properly.

The layout of membrane layer switches can vary, however they commonly include domes or responsive aspects to offer feedback to the user, boosting the total experience.In conclusion, membrane switches over offer as necessary elements in the style of dependable and long lasting control systems throughout various industries.

Report this page